The process of commercial asbestos removal: what to expect

Navigating the complexities of a commercial property that contains asbestos can be daunting for any building owner or employer. The potential for health risks, coupled with the intricate legal and procedural requirements, can make the prospect of asbestos removal seem overwhelming.

However, by understanding the process and partnering with a professional, licensed contractor, you can manage this challenge safely, efficiently, and with minimal disruption.

This blog post will demystify the process of commercial asbestos removal, providing a clear, step-by-step guide to what happens from the initial discovery of asbestos-containing materials (ACMs) to the final, certified clearance. The aim is to help you feel confident and in control, knowing exactly what to expect and what your responsibilities are.

The first step: the asbestos survey

Before any removal work can begin, a comprehensive asbestos survey is a legal and practical necessity. The purpose of this survey is to accurately locate and identify any ACMs within your building. This is not a task for a removal company, as it requires an independent, objective assessment.

A qualified asbestos surveyor, who is a separate entity from the removal contractor, will conduct a thorough inspection. They will take samples of any suspected materials, which are then sent to a UKAS-accredited laboratory for analysis.

The results from this analysis are crucial, as they will confirm the presence, type and condition of any asbestos. This detailed information forms the foundation of all subsequent planning and is essential for ensuring the correct safety procedures are followed.

From survey to strategy: risk assessments and planning

Once the survey is complete and the presence of asbestos is confirmed, the asbestos removal contractor’s work begins with meticulous planning. This stage is critical for ensuring the safety of all parties and compliance with strict regulations, such as the Control of Asbestos Regulations 2012.

The removal company will use the information from the survey to create a site-specific risk assessment and method statement (RAMS). This document is a detailed blueprint of the entire removal project. It outlines:

- The type and quantity of asbestos to be removed

- The specific control measures to be used to minimise airborne fibres, such as controlled wetting and the use of air filtration units

- The personal protective equipment (PPE) and respiratory protective equipment (RPE) for all on-site personnel

- The exact procedures for decontamination of the site, equipment and workers

- The plan for the safe handling, storage and transport of asbestos waste

- Emergency procedures in case of an unforeseen incident

This planning phase also involves notifying the Health and Safety Executive (HSE) of the planned work, a legal requirement for most licensed asbestos removal projects.

The removal process: containment, isolation and safe removal

With a solid plan in place, the physical removal work can commence. This is where the licensed professionals and their specialised equipment come in. The primary goal is to contain the asbestos and prevent the release of harmful fibres into the environment.

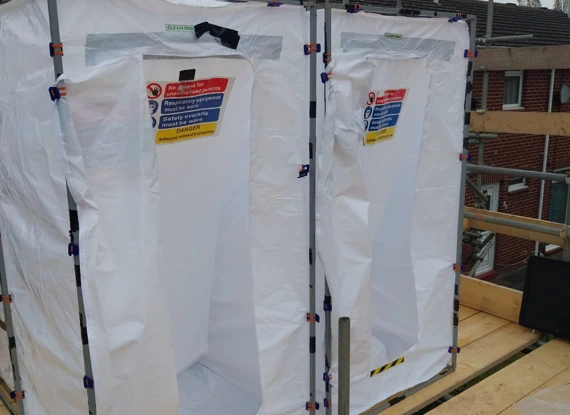

The work area is first sealed off using polythene sheeting to create a secure, airtight enclosure. This containment is placed under negative pressure using specialised air filtration units with HEPA filters. The negative pressure ensures that any potential airborne fibres are drawn into the filtration system rather than escaping into other parts of the building. Warning signs are posted to restrict access to the area, and only trained personnel wearing the appropriate PPE are allowed inside.

Using wet removal techniques to suppress dust and fibres, the asbestos-containing materials are carefully dismantled or removed. The material is double-bagged and sealed in accordance with hazardous waste regulations before being placed in a designated waste area.

Throughout the process, the team follows the pre-determined method statement, ensuring every step is carried out with the utmost care and attention to detail.

Minimising disruption to your operations

A common concern for business owners is the potential for downtime and disruption during the removal process. Professional asbestos removal companies like us understand that business continuity is a top priority. They work closely with clients to develop a removal plan that minimises the impact on commercial operations.

This can include scheduling work during evenings, weekends, or shutdown periods to avoid peak business hours. The use of contained and controlled enclosures means that, in many cases, work can proceed in one area of a building while other areas remain operational.

By providing a clear timeline and managing communication effectively, a professional contractor ensures you are always kept informed and that the process is as smooth as possible.

The all-clear: Final air monitoring and certification

The removal process is not complete until an independent, UKAS-accredited analyst confirms the area is safe for reoccupation. This is a crucial final step known as a four-stage clearance.

The four stages are:

- A preliminary check of site condition and job completeness: The analyst confirms all asbestos has been removed, waste disposed of, and the work area left clean and orderly.

- A thorough visual inspection inside the enclosure or work area: A detailed examination ensures no visible asbestos residues remain on surfaces, fixtures, or within the enclosure.

- Disturbance air monitoring: Air tests are carried out while the enclosure is deliberately disturbed to confirm fibre levels remain safely controlled.

- Final assessment after enclosure dismantling: The analyst inspects the wider area post-enclosure removal to ensure no asbestos contamination has escaped.

Only after all four stages have been successfully completed will the analyst issue a Certificate of Reoccupation. This certificate is your legal guarantee that the area is safe to be reoccupied and is a vital piece of documentation for your property’s records.

How Henderson Environmental can help

The safe and compliant removal of asbestos requires expertise, experience and a deep-seated commitment to health and safety. At Henderson Environmental, we pride ourselves on being a professional, transparent partner who guides clients through every step of the commercial asbestos removal process.

While we do not conduct asbestos surveys, we work seamlessly with your chosen asbestos surveyor. Our experienced and highly trained team, licensed by the Health and Safety Executive (HSE), specialises in the safe and efficient removal of all types of asbestos from commercial properties.

We support a wide variety of sectors, including education, leisure & retail, healthcare, commercial offices, construction, farming, public sector, and domestic & social housing.

From the meticulous preparation of RAMS to our efficient, discreet on-site procedures and the careful disposal of all waste, we handle every aspect of the project. Our goal is to provide a comprehensive, stress-free service that allows you to focus on your business while we handle the hazard. You can learn more about how we can assist with your commercial asbestos removal needs here.

By choosing a trusted and professional partner, you are investing in the safety of your business, your people and your future.

Contact us for further details.